Intellectual composite flexible pipe

FOR RUSSIA

QUALITY

ON THE MARKET

- DESCRIPTION

- SPECIFICATIONS

- GUARANTEES

Basically, worldwide oil production is carried out by sucker-rod pumps. With increasing inclined and horizontal wells, oil production using sucker-rod pumps became more difficult, problems with eccentric wear, broken rods, idle work, asphalt-resin-paraffin and salt deposits appeared

To reduce the influence of these factors, the rodless method of well operation is applied. Currently, in oil production using submersible electric motors, pump-compressor pipes used of traditional construction, in which clamps are used to fasten the cable to the pipe. This method of extraction does not solve all problems, mainly with the wear of the pipe. There is an open problem with cable wear (for example, scratching the cable leads to a decrease in its characteristics, breaks and wear of the submersible equipment, as a result in some cases it is impossible to lift the equipment to the surface and the well becomes inoperative)

Given the above problems, our company began the development and production of an intellectual composite flexible pipe. Using it in oil production is the best solution.

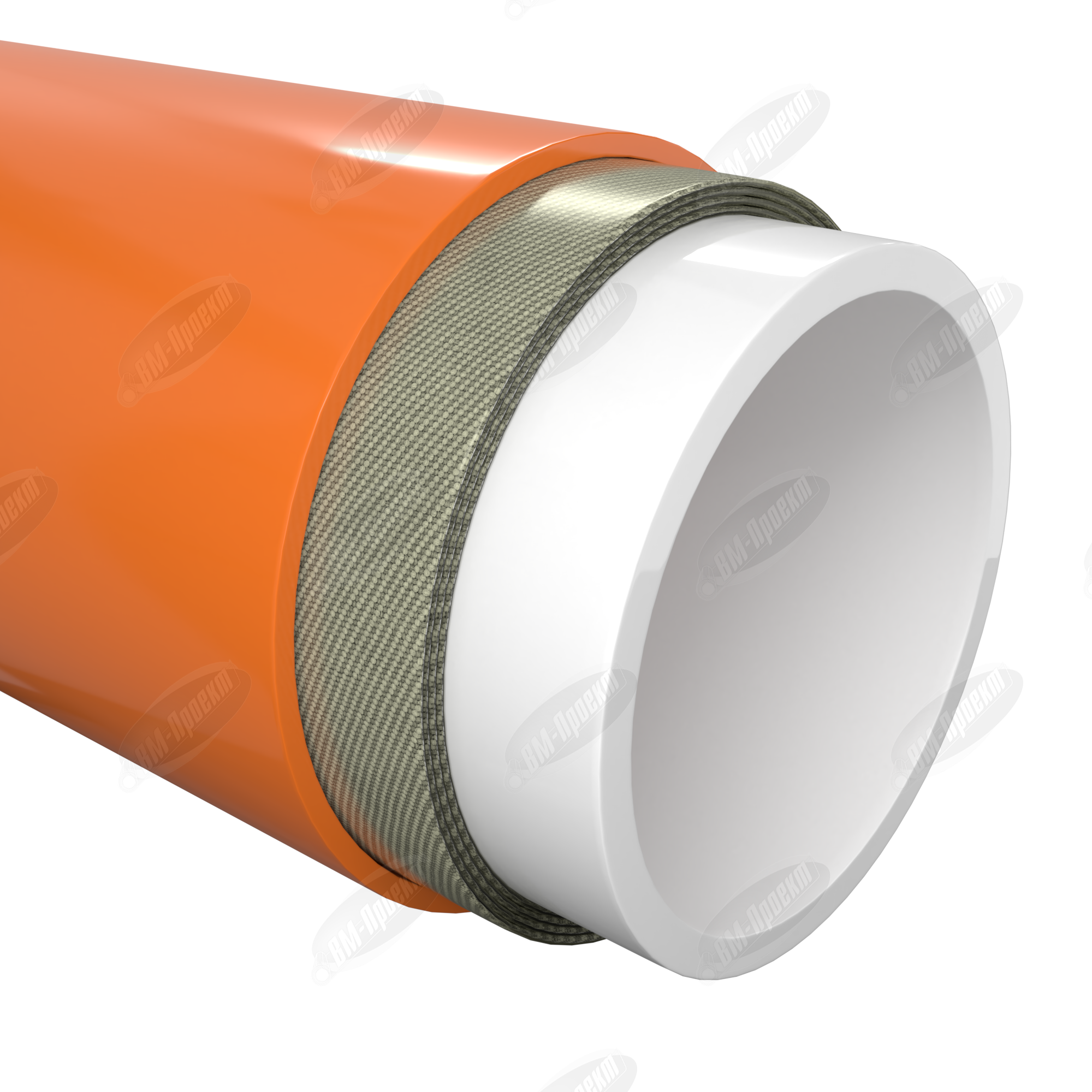

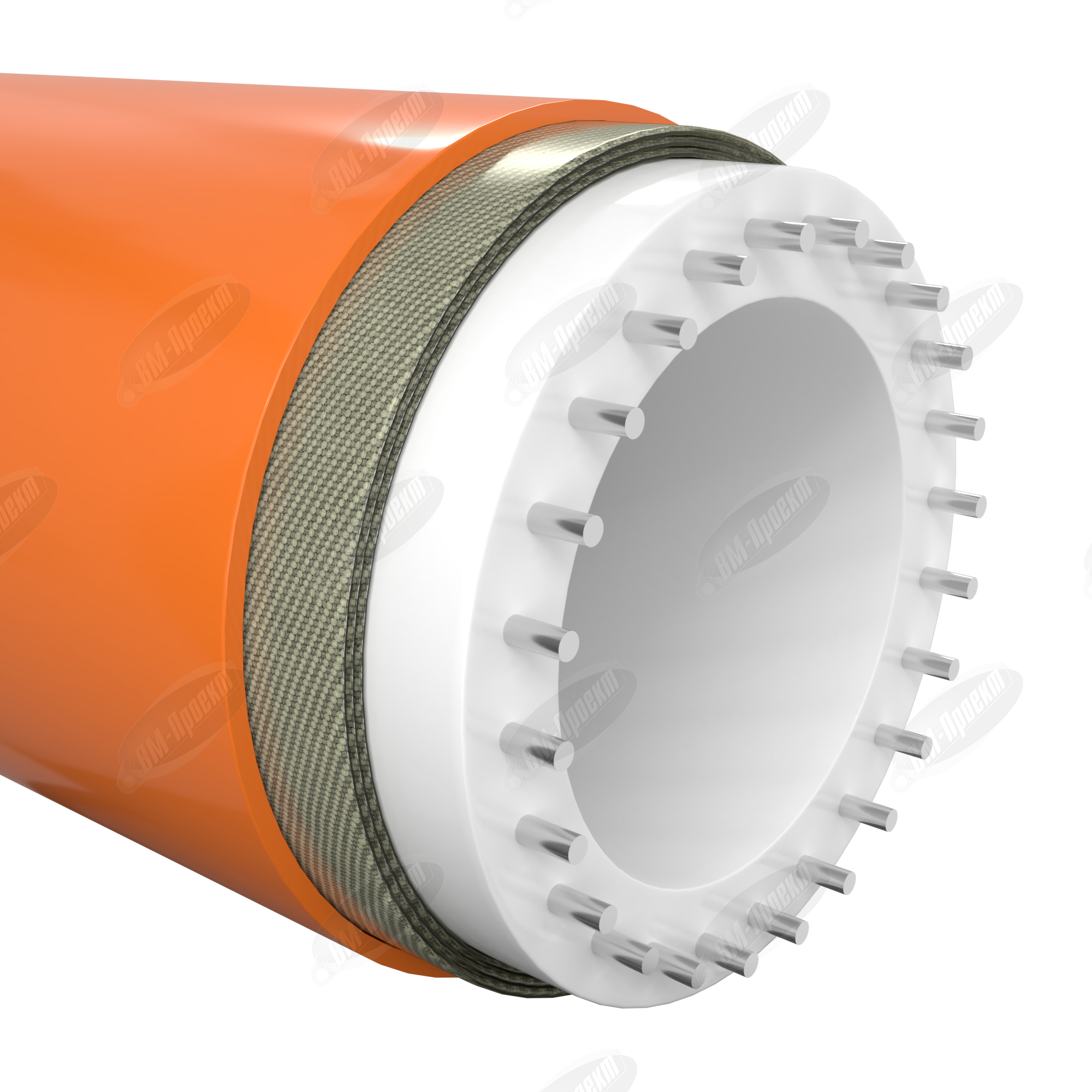

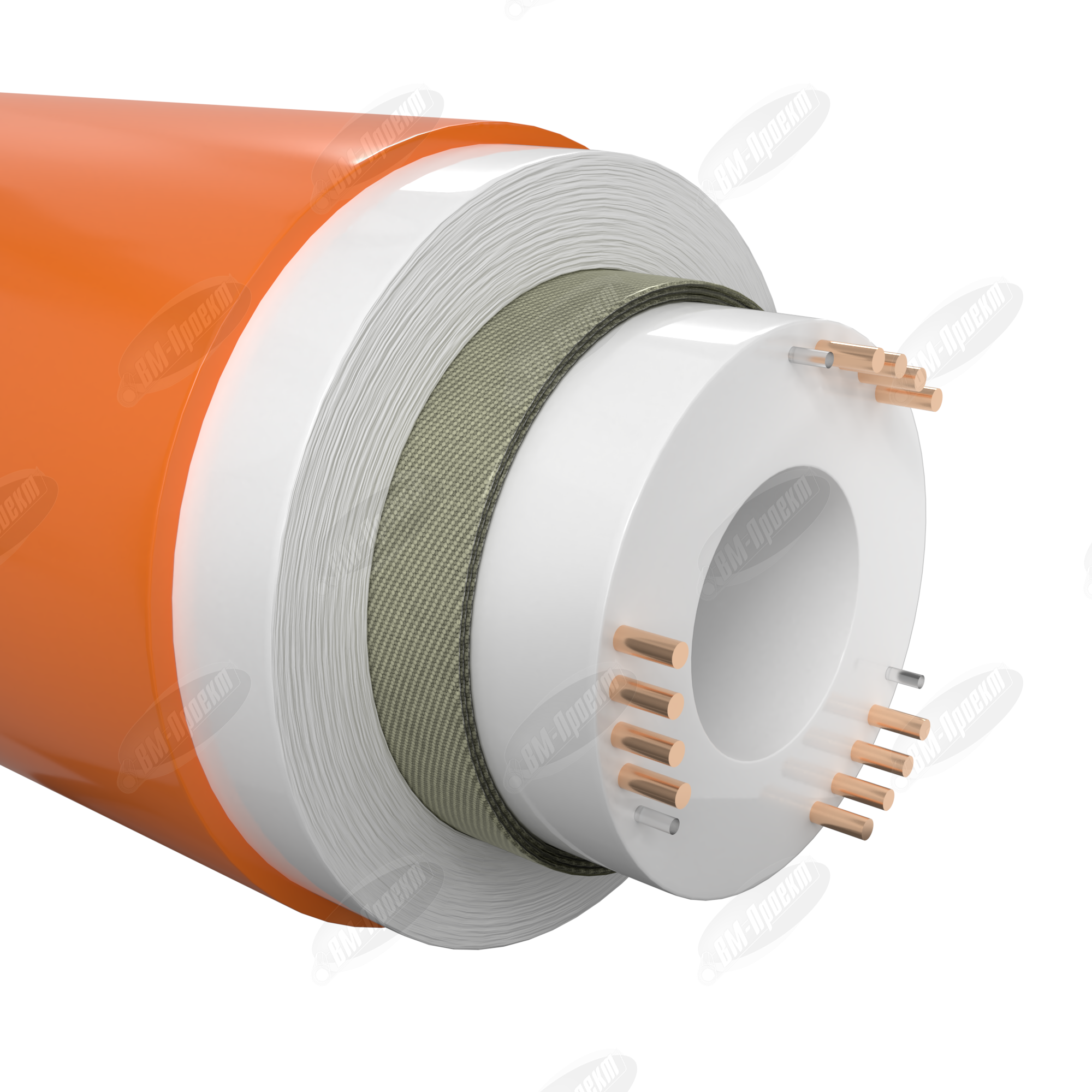

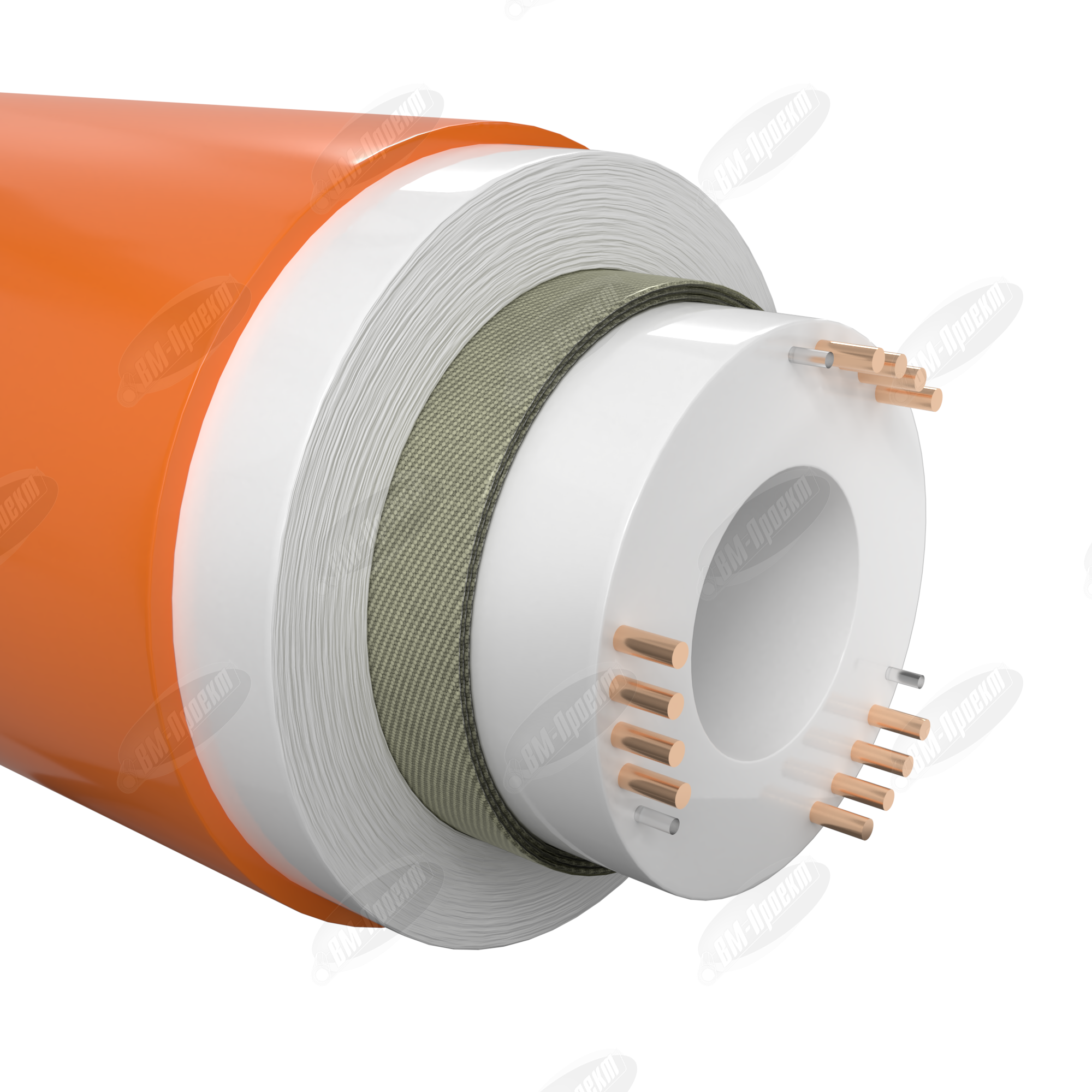

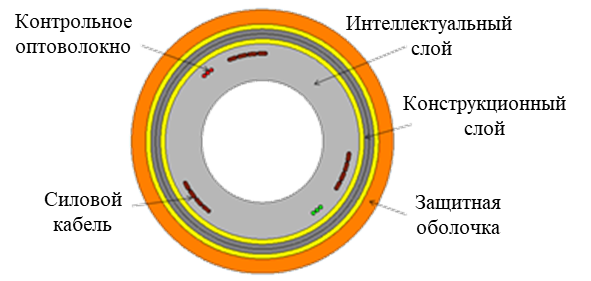

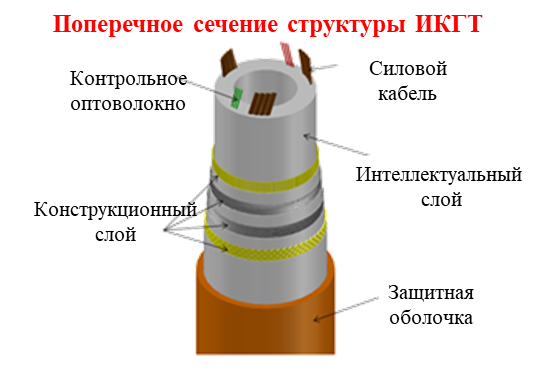

Сonstructive features:

- The intellectual layer can be made of ultra high molecular weight polyethylene, PA, PVDF and other materials. It plases the power cable, heating wire, optical fiber or signal wire

- The сonstructional of the layer consists mainly of reinforced fibers, which allows it to withstand the various mechanical properties. The fibers are made of aramid, carbon fiber, fiberglass or other fibers high quality

- Protective shell. The function of this layer derives from the name. It serves to protect pipe during transportation, chute-lift operations and exploitation.

Benefits:

- Intellectual composite flexible pipe has the functions of transmission of electricity, heating and heat preservation, which prevents the formation of scaling and paraffin

- Excellent corrosion resistance to hydrogen sulfide H2S and carbon dioxide CO2

- Durability, smooth inner surface of the pipe, the coefficient of resistance to flow is small, low thermal conductivity is 1% of the metal. Efficiency of transport, economy of thermal energy

Intellectual composite flexible pipe has a length of up to 3000 m in length, the absence of connections on the pipe significantly improves performance and reduces the risk of damage to the pipe during operation

Intellectual composite flexible pipe is equipped with optical fiber or wire for data transmission. It can in real time obtain the parameters of a submersible pump, the presence of fluid in the well, it is easier to reach the oil field, and also carry out remote monitoring and control

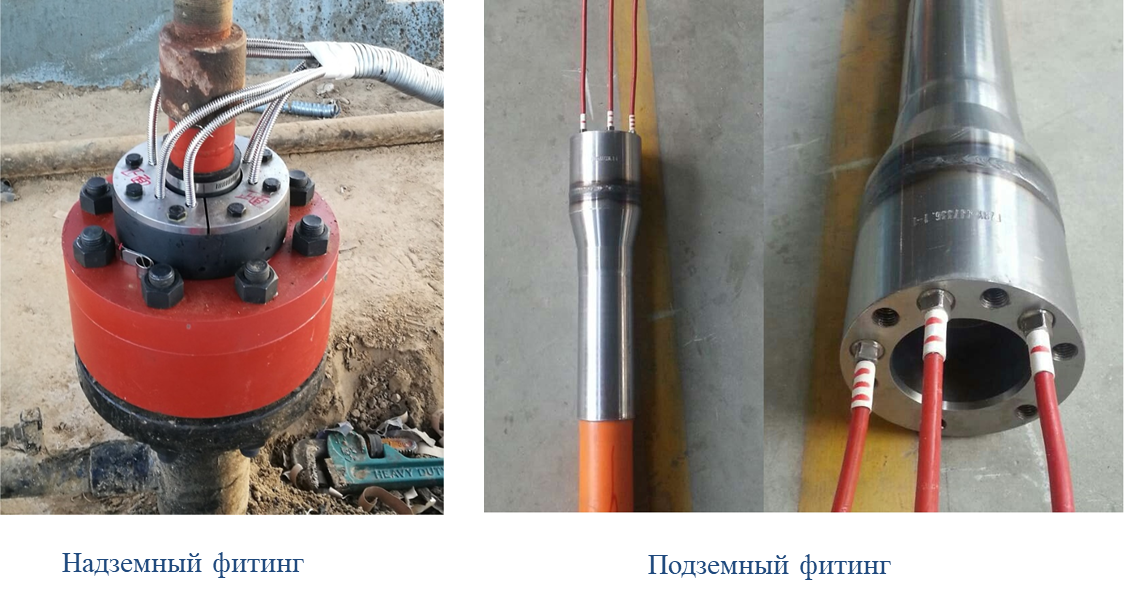

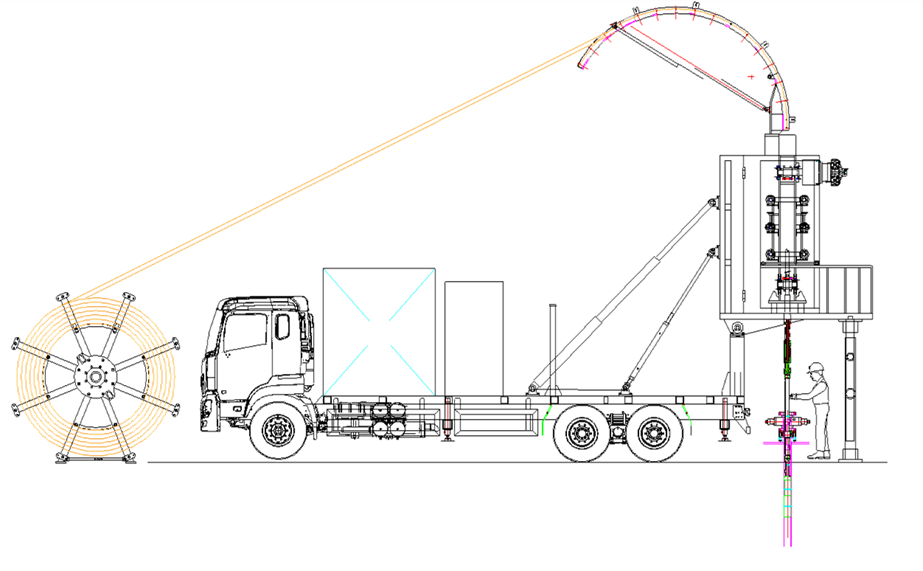

Special aboveground and underground fittings have been developed for oil production using Intellectual composite flexible pipe  The composite flexible pipe Intellectual installation consists of two parts: a device for winding and unwinding a pipe string. Injector mounted on the car.

The composite flexible pipe Intellectual installation consists of two parts: a device for winding and unwinding a pipe string. Injector mounted on the car.

Tensile test table

| Test temperature | Rupture sprain(KN) | Elongation value at rupture(%) | Average of tensile rupture(KN) | Average coefficient of elongation at rupture(%) |

| Room temperature | 411 | 4.58 | 411 | 4.5 |

| Room temperature | 420 | 4.37 | ||

| Room temperature | 402 | 4.50 |

Specifications

| Maximum working pressure(MPa) | 10 | ~ | 50 | ||

| Working temperature ℃ | 60 | 90 | 120 | 150 | 200 |

| The material of the Inner layer | PE-HT | PA | PVDF | MFA | PFA |

| The material of the outer protective layer | PE-HT | PA | PVDF | MFA | PFA |

| Layer to enhance | Glass、Carbon、Aramid Fiber | ||||

| Nominal diameter size(”) | 1.0 | 1.5 | |||

| Flow diameter | 25 | 36 | |||

| External diameter | 63 | 73 | |||

| Weight | 3 | 3.5 | |||

| Minimum bending diameter | 1.8 | 2 | |||

| Maximum axial tension | 300 | 300 | |||

| Power | 3~30 | 6~60 | |||

| Voltage | 1500 | 1500 | |||

The service life of at least 50 years. The warranty period is 2 years from the date of manufacture.