Rocky sheet

FOR RUSSIA

QUALITY

ON THE MARKET

- DESCRIPTION

- SPECIFICATIONS

- GUARANTEES

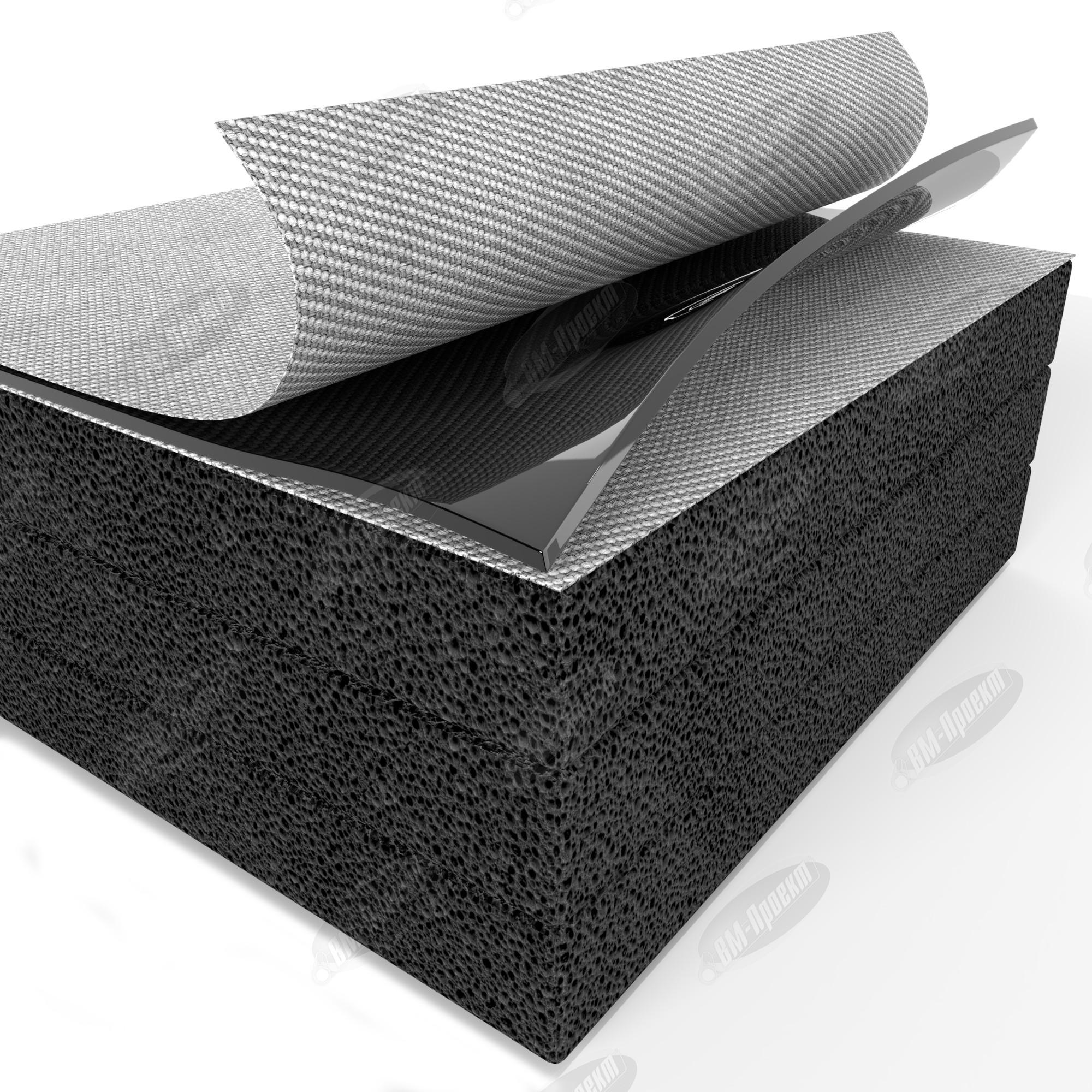

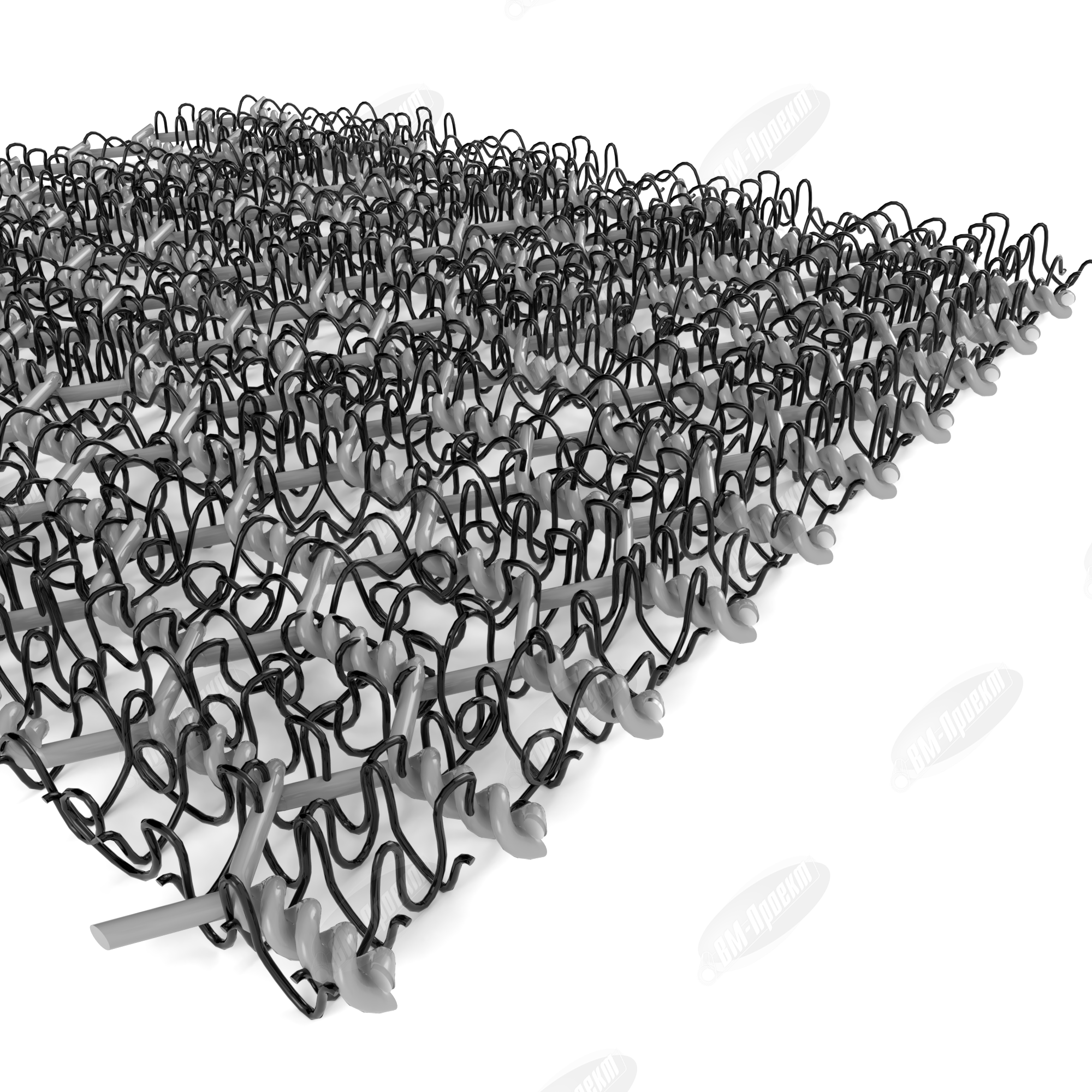

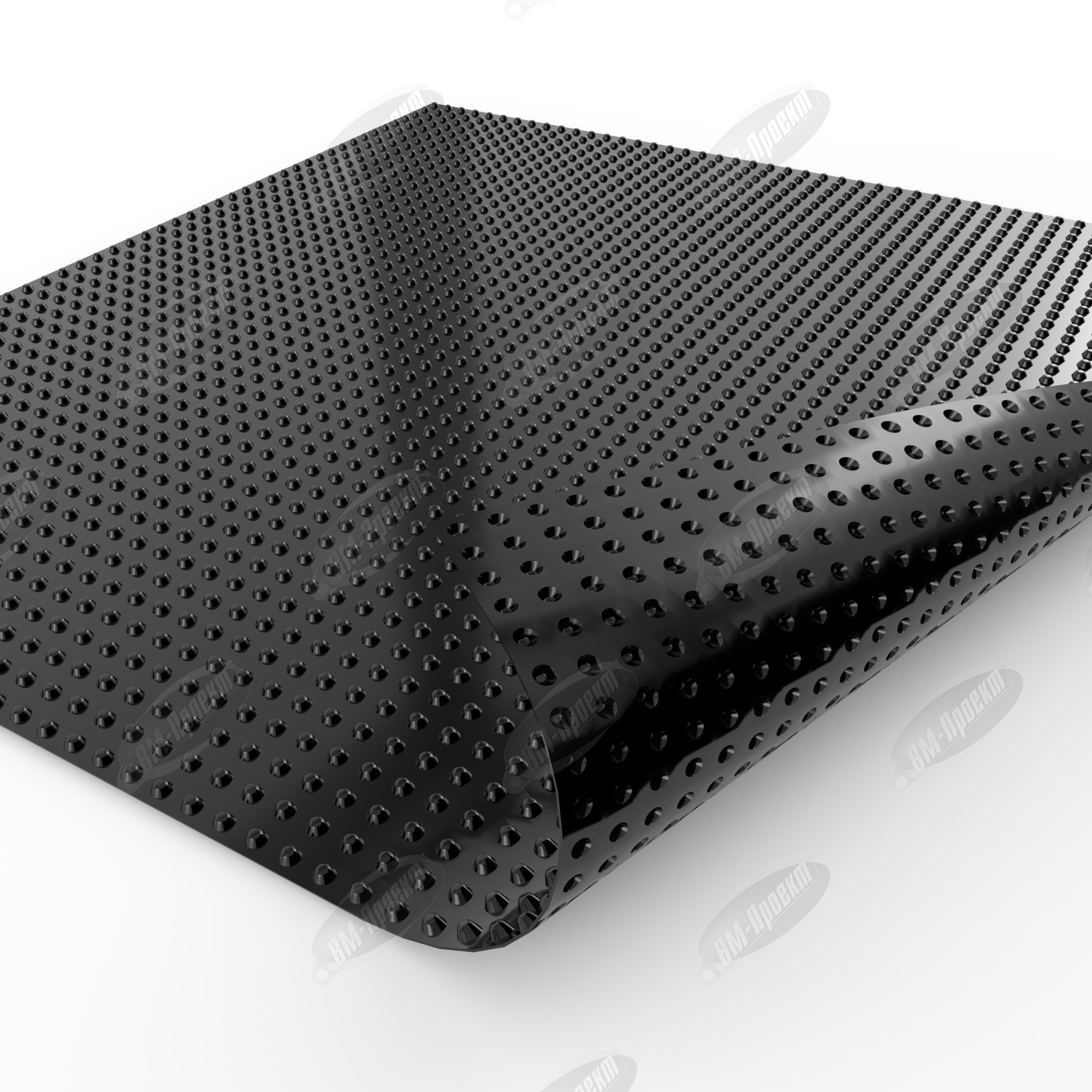

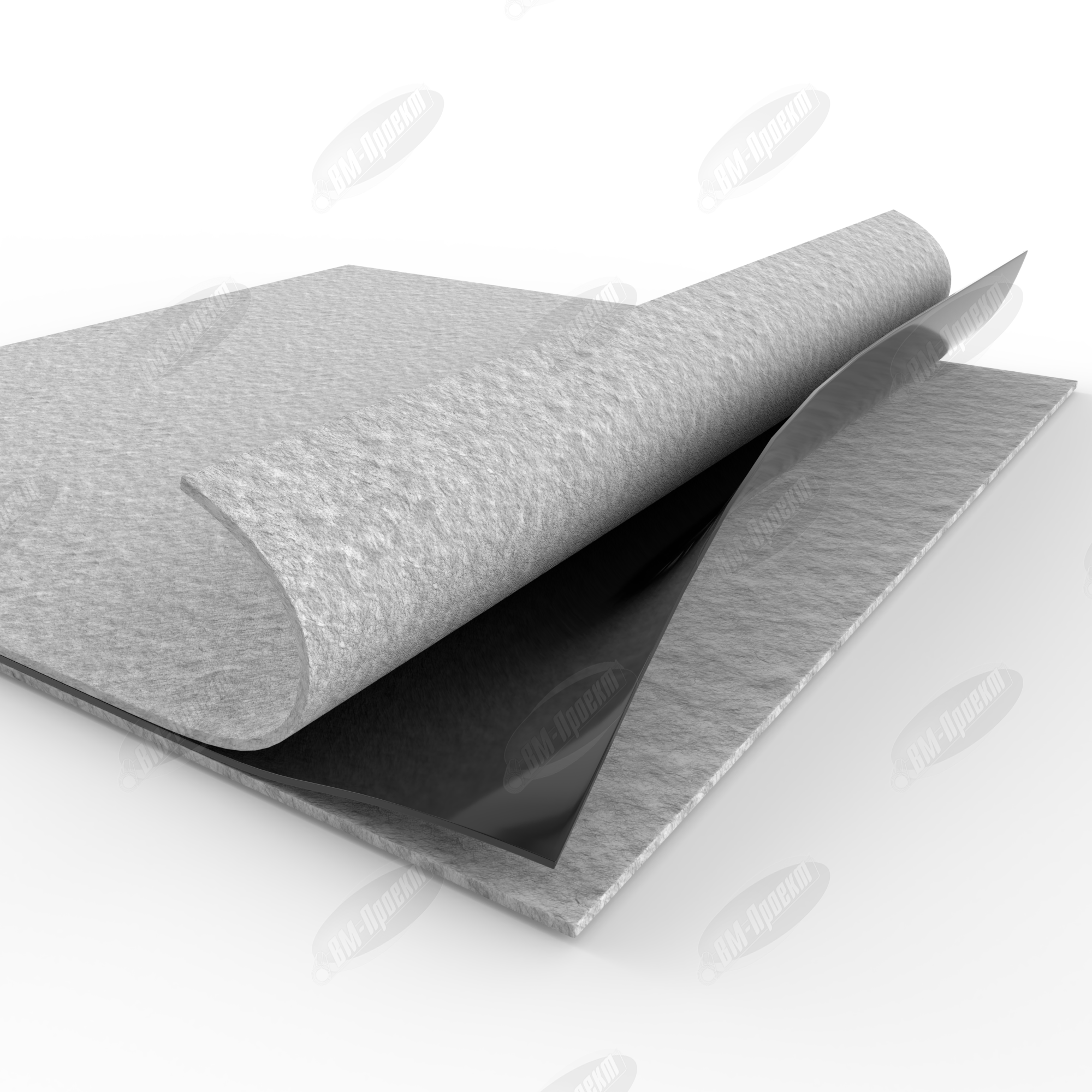

Polymer rocky sheet is designed to protect the insulated surface of pipelines with a diameter of up to 1420 mm. Including mechanical damage when laying them in rocky and permafrost (permafrost) soils, including when the backfill soil contains inclusions of screes, gravel, pebbles, crushed stone and larger solid inclusions in all macroclimatic areas at ambient temperatures from 60C below zero to 50C above zero. The polymeric rock sheet is produced according to TU2246-001-96017324-2010 (with a change in No1) .I t is a structure made by the extrusion method of single-sided lamination of non-woven synthetic material with high-pressure polyethylene, which reliably holds layers of polymers (woven and non-woven) with subsequent perforation. In agreement with the customer, it is allowed to manufacture a rock sheet of a polymer without perforation. To protect the isolated surface of curvilinear sections of pipelines, a tape made of a rocky polymer sheet, with a width of 0.2 m to 0.6 m and a length of up to 10 m is used. To protect the insulated surface of pipelines from mechanical damage by cast iron weights and (or) reinforced concrete weighting materials of the covering and saddle types, protective mats made of a rocky polymer sheet is used. To ensure the cathodic protection of pipelines from corrosion, a rocky polymer sheet with perforations is used. Considering the different conditions of pipeline laying, the rocky polymer sheet is produced in the usual version “O” with a polyethylene laminating layer thickness of 2 mm and the reinforced version Y with a polyethylene laminating layer – 3mm. Polymeric rock sheet is an environmentally friendly product, which is confirmed by sanitary and epidemiological conclusion No 50.99.04.224.II.000917.01.09 of January 26, 2006. Polymer rock sheet has certificates of conformity “VNIIGaz” and GOST R, as well as permission to use.

| Title | Defined parameters | Dimension | Value indicator | |

| Impact resistance | Impact resistance at 20 ° С above zero | Joule,at least | 54 | 65 |

| Impact resistance at 40 ° С below zero | ||||

| Breaking load | Explosive loading in the longitudinal and cross directions | kH,at least | 1.1 | 1.3 |

| Relative extension | Relative elongation in the longitudinal and transverse directions | %,at the most | 60 | 50 |

| Resistance in aggressive environments | Value of breaking load in relation to the initial value | %,at least | 95 | 95 |

| Abrasion resistance | Value of breaking load in relation to the initial value | %,at least | 95 | 95 |

| Flexibility | Flexibility at 40 ° С below zero | – | No damage | |

| Transient resistance | Transient resistance after soaking in a solution of % NaCl for 48 hours | Ом*м2, at the most | 120 | |

Rocky sheet parameters

| Brand of the rocky sheet | Outer diameter of the protected pipelineа, mm | Length, mm, not less | Width B (size along the pipeline), mm, not less | Thickness, mm, not more | Mass, execution “O”, kg | Mass, execution”U”, kg |

| СЛП-1420 | 1420 | 4700 | 2400 | 5 | 24,7±2,1 | 35,1±2,1 |

| СЛП-1220 | 1220 | 4060 | 2400 | 5 | 21,3±1,8 | 30,2±1,8 |

| СЛП-1020 | 1020 | 3440 | 2400 | 5 | 18,0±1,5 | 25,5±1,5 |

| СЛП-820 | 820 | 2820 | 2400 | 5 | 14,8±1,3 | 21,0±1,3 |

| СЛП-720 | 720 | 2500 | 2400 | 5 | 13,2±1,2 | 18,7±1,2 |

| СЛП-630 | 630 | 2220 | 2400 | 5 | 11,7±1,0 | 16,6±1,0 |

| СЛП-530 | 530 | 1900 | 2400 | 5 | 10,0±0,9 | 14,2±0,9 |

| СЛП-426 | 426 | 1580/td> | 2400 | 5 | 8,3±0,7 | 11,8±0,7 |

| СЛП-377 | 377 | 1425 | 2400 | 5 | 7,4±0,6 | 10,6±0,6 |

| СЛП-325 | 325 | 1260 | 2400 | 5 | 6,6±0,6 | 9,4±0,6 |

| СЛП-273 | 273 | 1090 | 2400 | 5 | 5,8±0,5 | 8,2±0,5 |

| СЛП-219 | 219 | 920 | 2400 | 5 | 4,8±0,4 | 6,8±0,4 |

Polymer rocky sheet ZK – PRS

| Brand of the rocky sheet | Outer diameter of the protected pipeline, mm | Length, mm, not less | Width B (size along the pipeline), mm, not less | Thickness, mm, at the most | Mass, execution “O”, kg | Mass, execution “U”, kg |

| ЗК-СЛП-УБО-1420,ЗК-СЛП-УБО-М-1420 | 1420 | 3600 | 1600 | 5 | 11,5±0,5 | 17,3±0,5 |

| ЗК-СЛП-УБО-1220,ЗК-СЛП-УБО-М-1220 | 1220 | 3200 | 1800 | 5 | 11,5±0,5 | 17,3±0,5 |

| ЗК-СЛП-УБО-1020,ЗК-СЛП-УБО-М-1020 | 1020 | 2400 | 1900 | 5 | 9,1±0,5 | 13,7±0,5 |

| ЗК-СЛП-УБО-М-820 | 820 | 2400 | 1900 | 5 | 9,1±0,5 | 13,7±0,5 |

| ЗК-СЛП-УБО-М-720 | 720 | 2000 | 1900 | 5 | 7,6±0,5 | 11,4±0,5 |

| ЗК-СЛП-УБО-530,ЗК-СЛП-УБО-М-530 | 530 | 1400 | 1200 | 5 | 3,4±0,5 | 5,0±0,5 |

Warranty – 1 year The service life of the rock sheet polymer is not less than the service life of pipeline