FOR RUSSIA

QUALITY

ON THE MARKET

- DESCRIPTION

- SPECIFICATIONS

- GUARANTEES

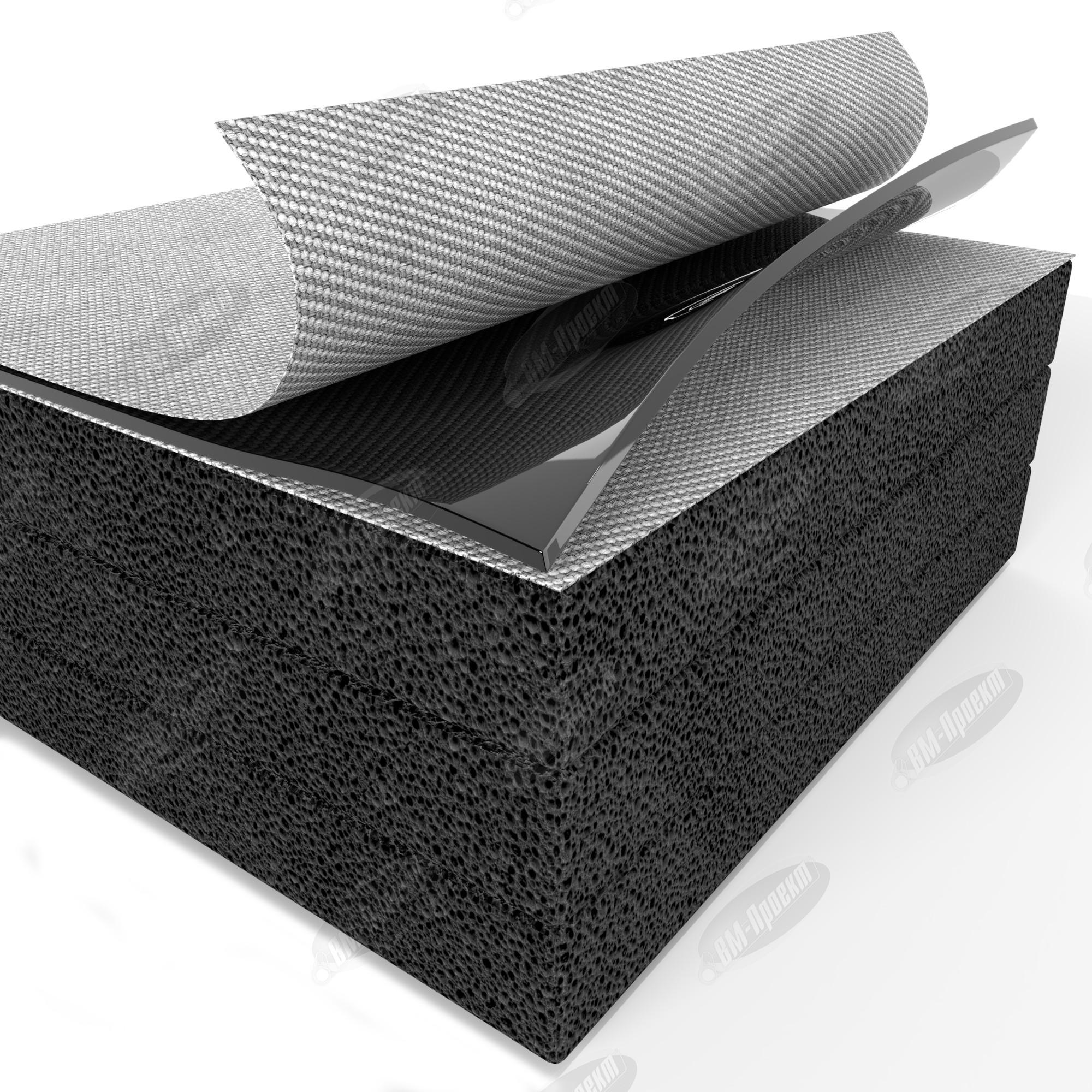

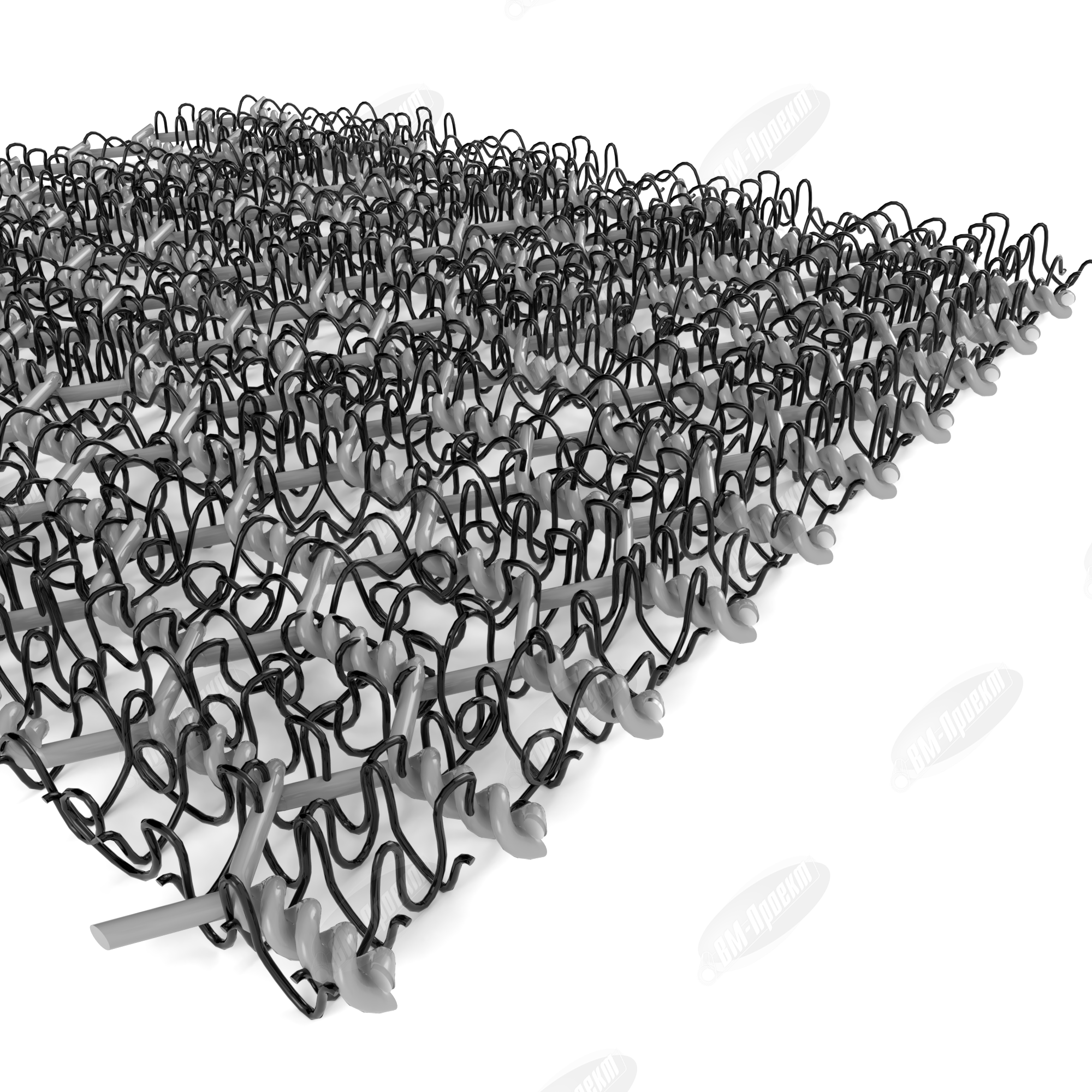

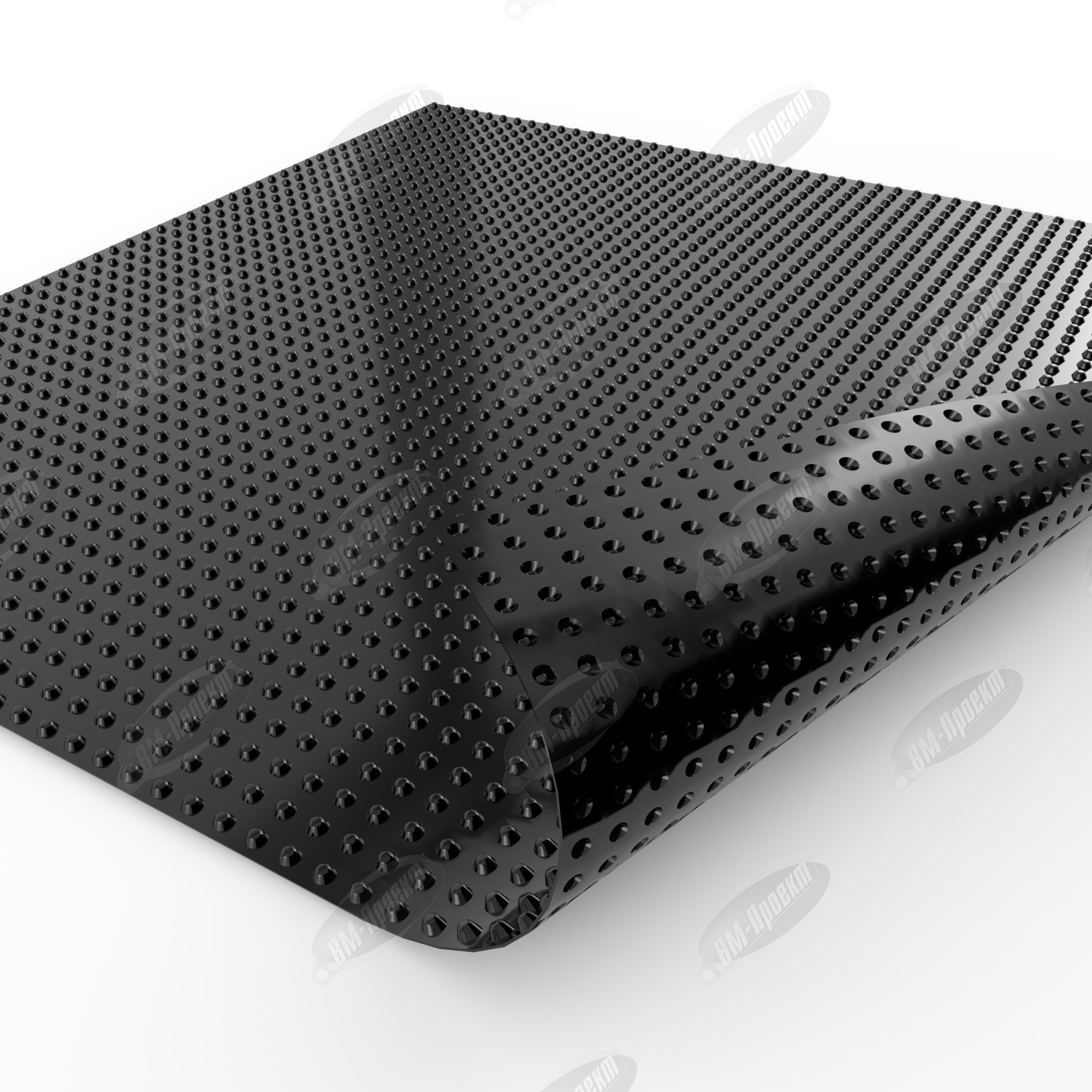

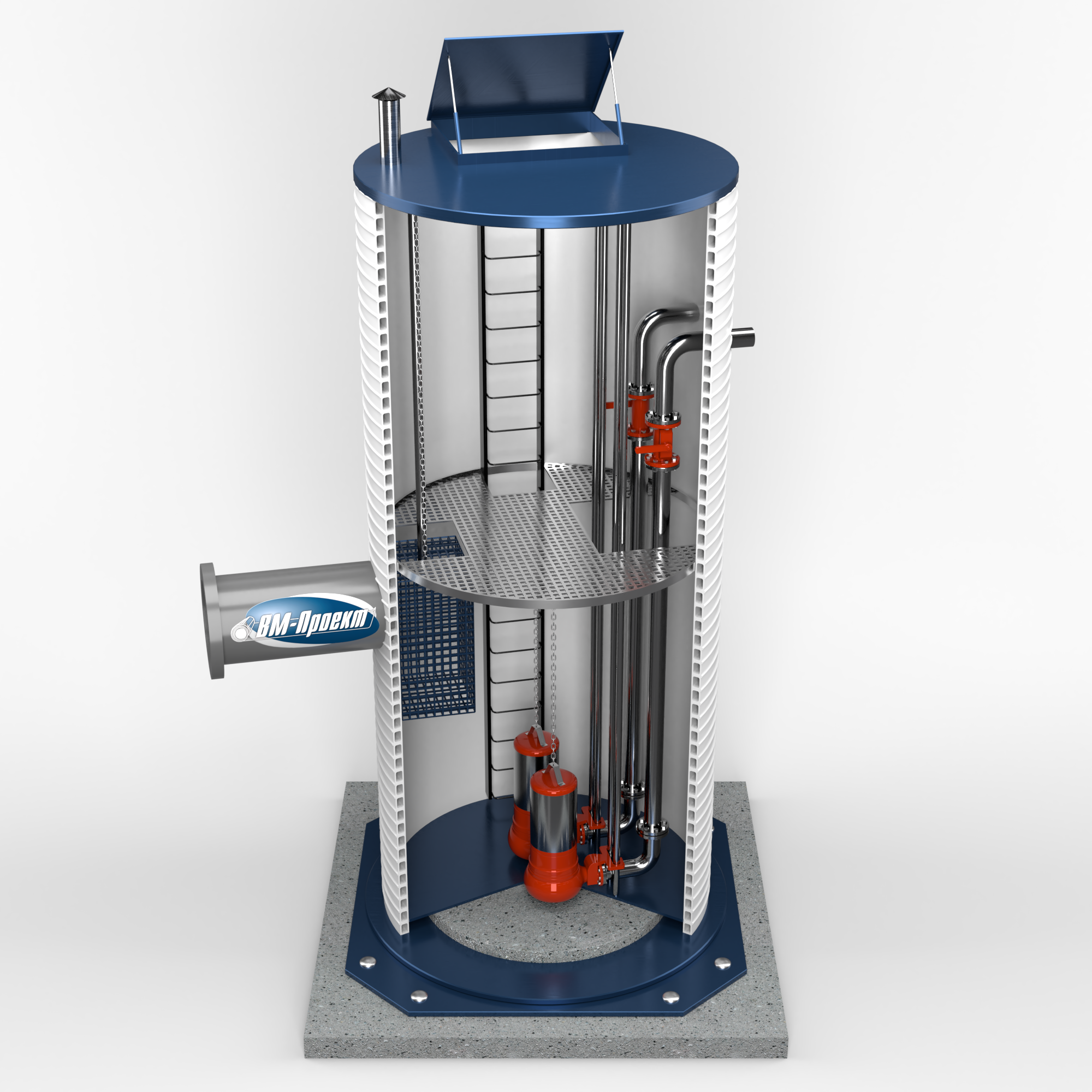

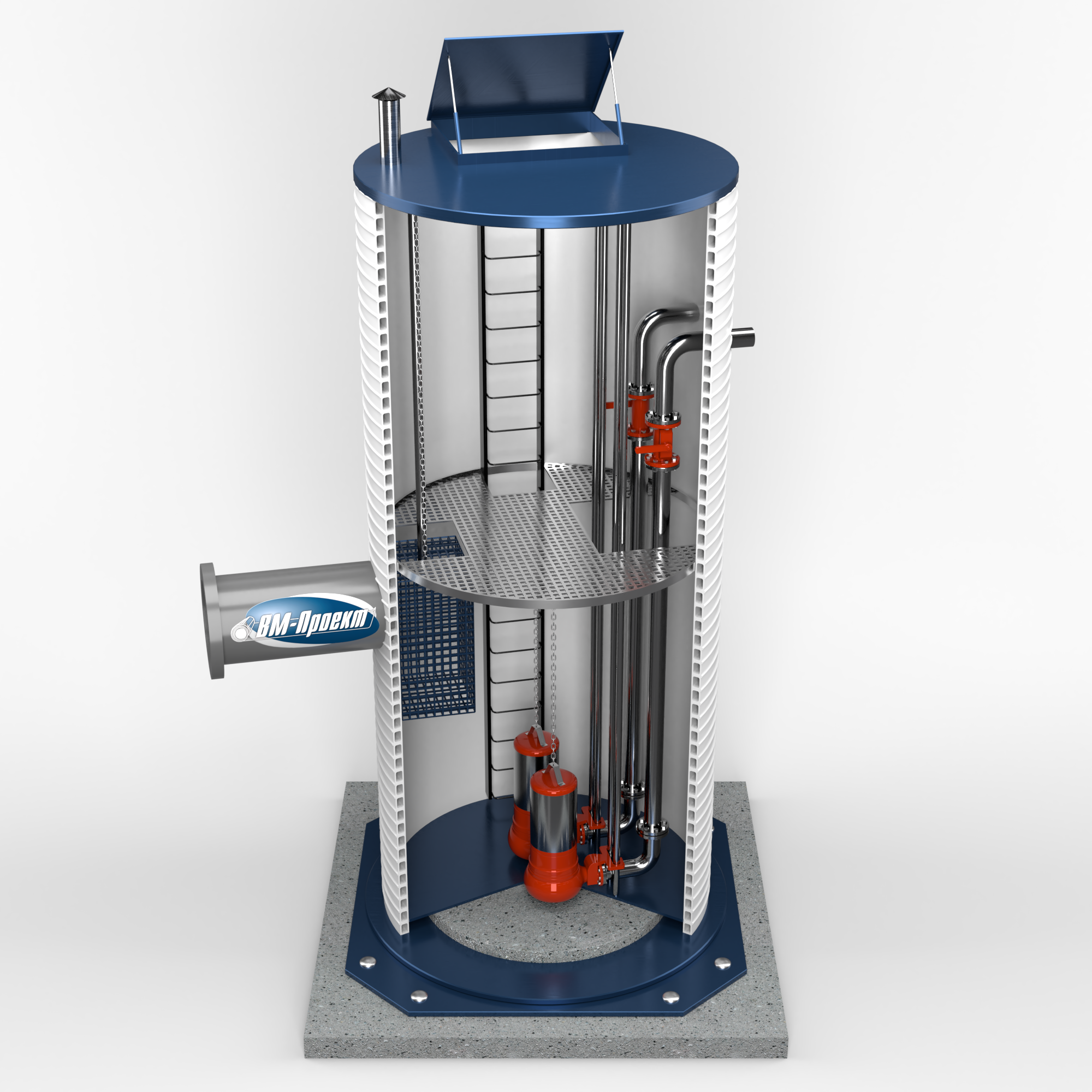

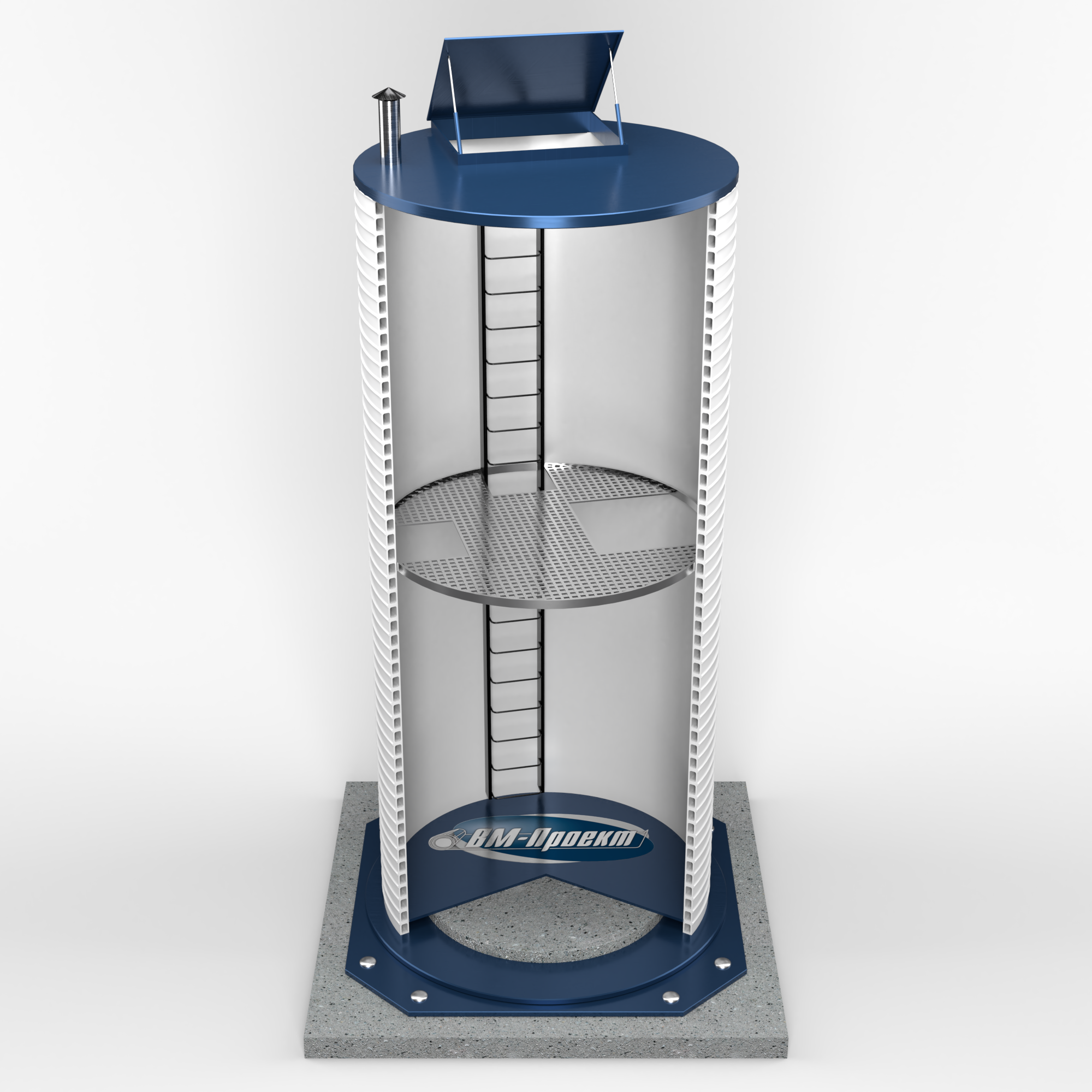

The sewage pumping station serves for lifting and pumping fecal, household, groundwater and storm drains to the location of the nearest sewage treatment plant. The sewage pumping station is produced from modern polyethylene pipe brands and has all the necessary certificates and permits. The sewage pumping station have a set of technical and operational characteristics that are optimal for use in difficult climatic conditions and earthquake-prone areas. The equipment has an increased level of security and copes with its tasks in conditions of low temperatures and moving soils. Almost all modern-type sewage pumping stations have a hermetic lid, a platform and a ladder for servicing equipment. Sewage pumping stations are equipped with compact and powerful submersible pumps with built-in electric motor protection, and a wide operating temperature range for pumping liquids. Replacement of the pump is made within an hour without interruptions in the work. Among other advantages are the following: corrosion resistance; durability (service life of containers not less than 50 years) lightness (don’t pose an additional load on the soil, the weight of the spiral pipe is almost 14 times less concrete) Sewage pumping stations differ in cost and have many varieties, which are divided by place of installation, type of control, type and amount of pumped run-off, as well as selected pumping equipment

The corps diameter varies from 1000 to 2800 mm. Height from 2 to 12 m Weight (without) pump from 250 to 5900 kg.

The warranty period is 2 years from the date of manufacture, subject to the conditions of transportation and storage.