The BALIT wearing system

FOR RUSSIA

QUALITY

ON THE MARKET

- DESCRIPTION

- SPECIFICATIONS

- GUARANTEES

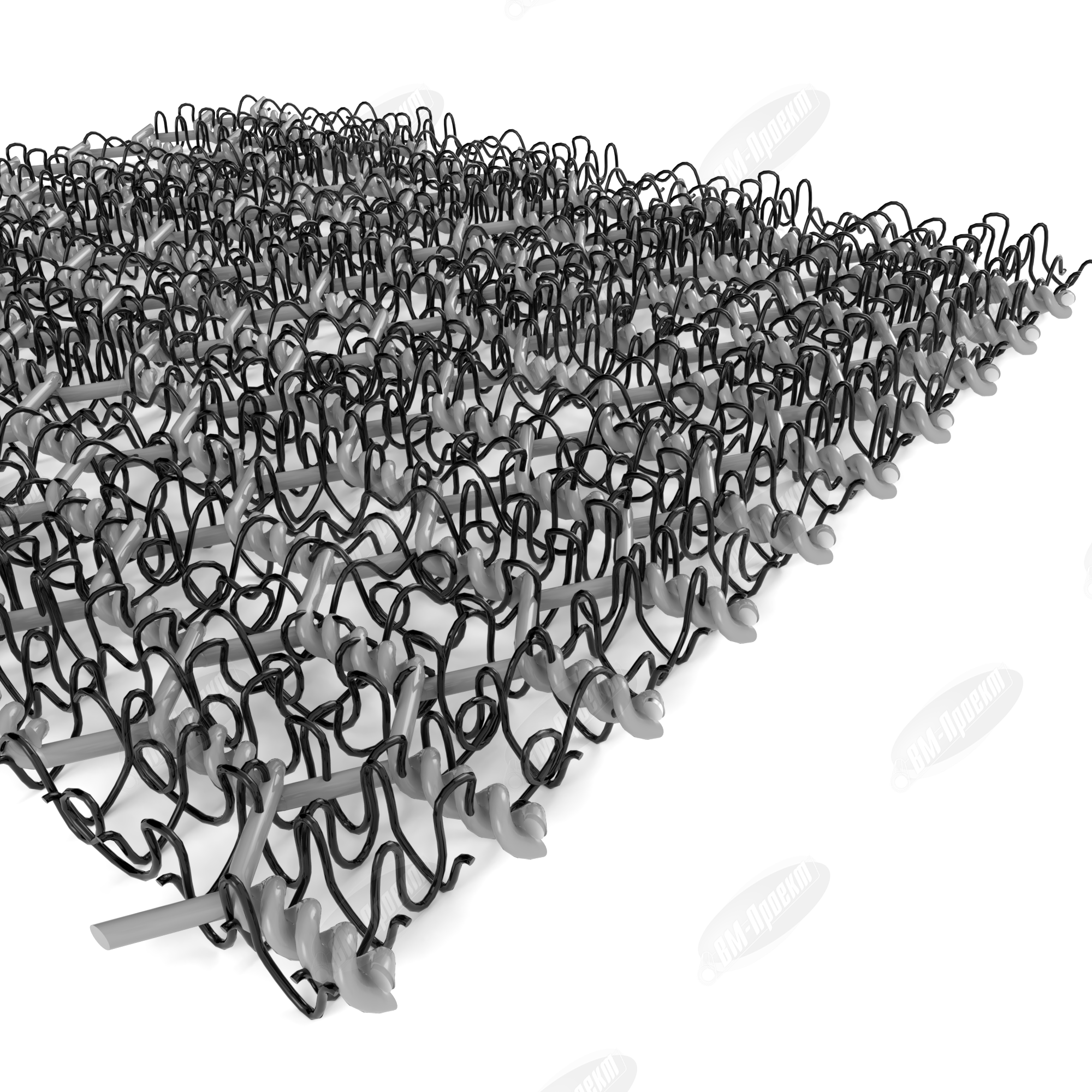

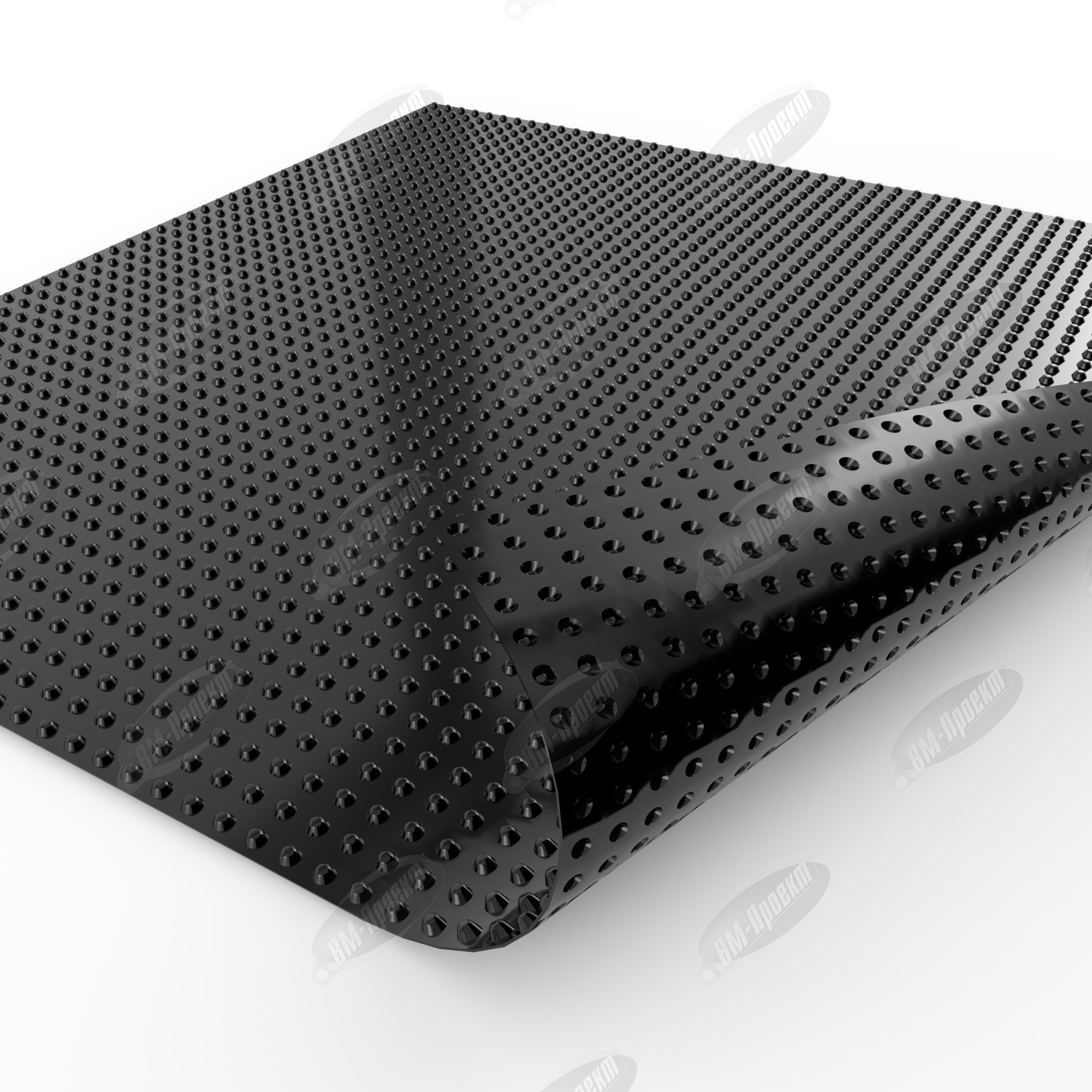

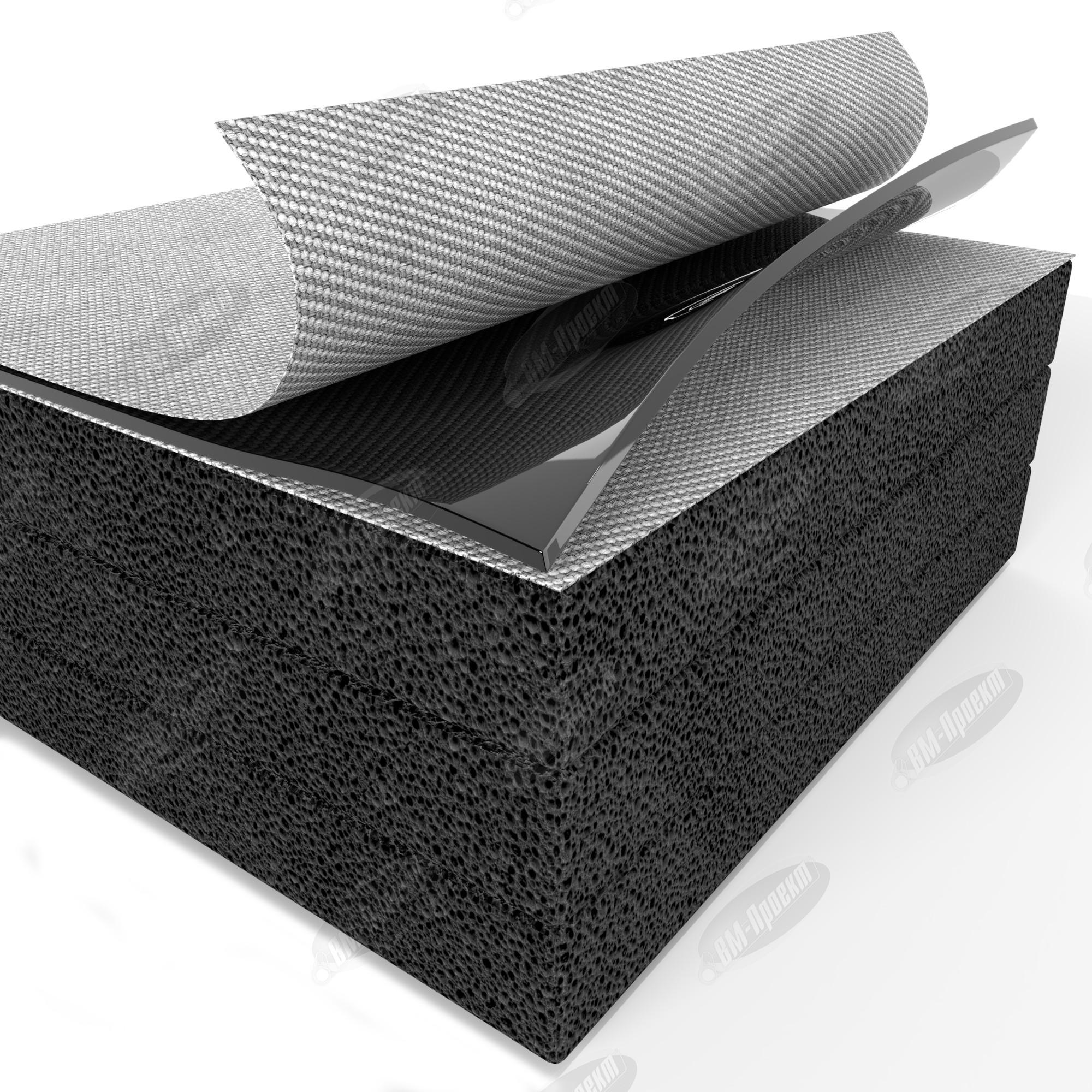

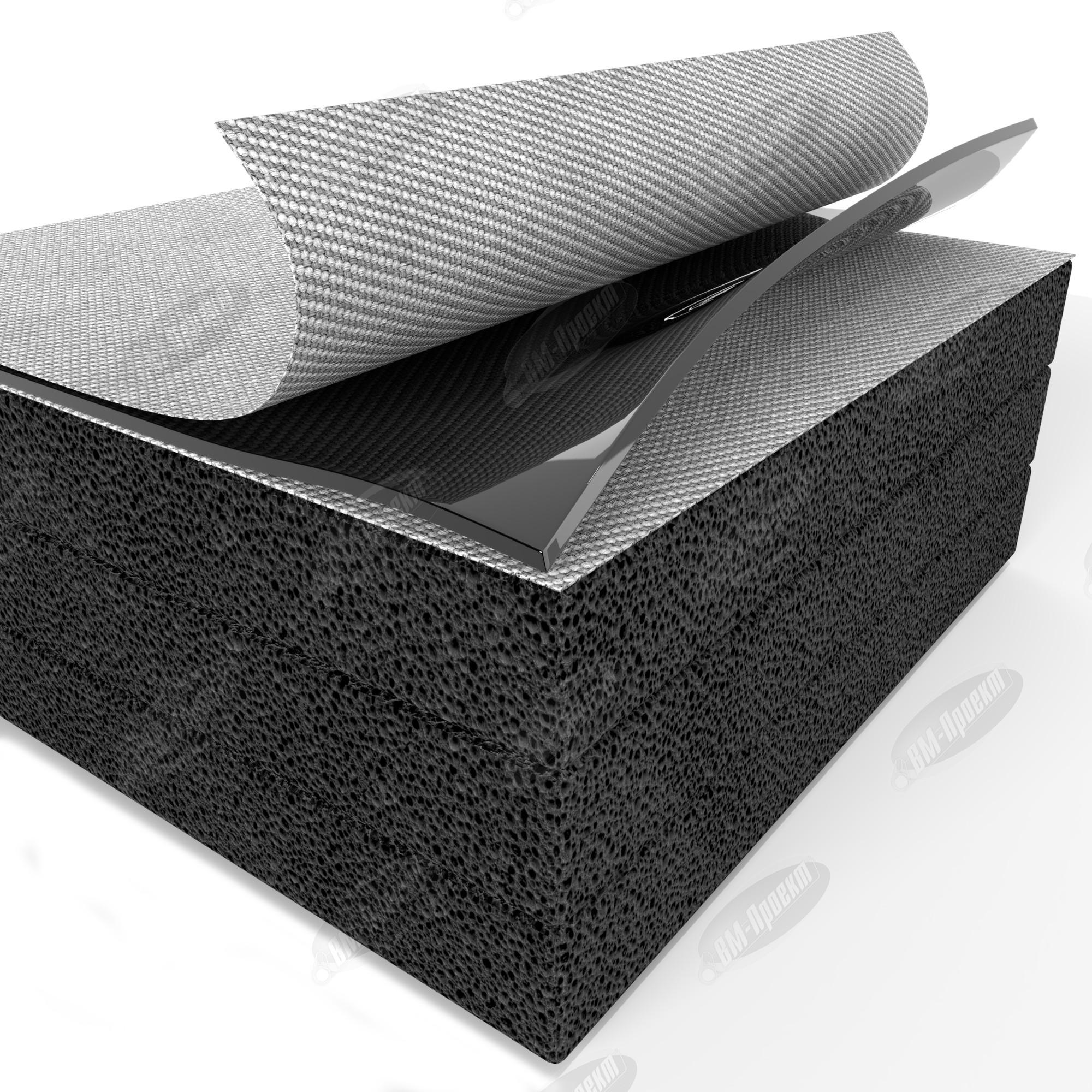

The BALIT wearing system to protect the external anticorrosion coating of pipelines with a diameter of up to 1,420 mm inclusively is manufactured in accordance with TU 22.21.4-007-96017324-2017 and used for: protection of external anticorrosion coating of pipelines with a diameter of up to 1420 mm inclusively from mechanical damage when using cast iron, reinforced concrete weights protection of the pipeline when it dragging a whip and (or) backfilling The BALIT wearing system is a structure made of a polymer sheet laminated on both sides with biaxial fiberglass and a sheet of polyethylene foam, used as a substrate, fixed to the outer anti-corrosion coating of the pipeline by help of clamps-ties. Wearing lining system is used in all macroclimatic areas of the category UHL1 according to GOST 15150 at ambient temperature from 60°C below zero to 50°C above zero

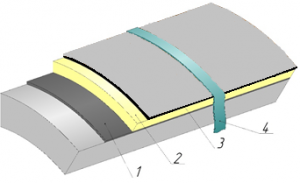

The location of WS with substrate on pipeline

- the pipeline with external anticorrosion coating;

- Substrate

- Sheet

- Montage tie strap

Picture one – The location of WS with substrate on pipeline

Physico-mechanical characteristics of WS

| Title | Outside diameter of protected pipeline, mm | Length of the layer, mm ±30 | Length of the substrate, mm ±30 | Thickness, mm ±1 | Mass, kg |

| WS -1420 | 1420 | 4700 | 4477 | 30 | 32,6±2 |

| WS -1220 | 1220 | 4060 | 3849 | 30 | 28,1±2 |

| WS -1020 | 1020 | 3440 | 3221 | 30 | 23,7±1,5 |

| WS -820 | 820 | 2820 | 2593 | 30 | 19,3±1,5 |

| WS -720 | 720 | 2500 | 2279 | 30 | 17,0±1,5 |

| WS -630 | 630 | 2220 | 1997 | 30 | 15,04±1 |

| WS -530 | 530 | 1900 | 1683 | 30 | 12,8±1 |

| WS -426 | 426 | 1580 | 1356 | 30 | 10,5±0,7 |

| WS -377 | 377 | 1425 | 1202 | 30 | 9,6±0,7 |

| WS -325 | 325 | 1260 | 1039 | 30 | 8,2±0,7 |

| WS -273 | 273 | 1090 | 876 | 30 | 7,0±0,5 |

| WS -219 | 219 | 920 | 706 | 30 | 5,8±0,5 |

The maintenance period – 12 months since manufacture Service life – At least the remaining service life of the pipeline while respecting the transportation, storage and usage